rockwell hardness test of metals|rockwell hardness testing machine diagram : trading There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more 30/06/2021 06h00 Atualizado há 2 anos. Fortaleza e Chapecoense entram em campo pela oitava rodada da Série A do Campeonato Brasileiro nesta quarta-feira, a partir das 16h (de Brasília), na Arena Castelão, na Capital cearense. O ge acompanha todos os lances em Tempo Real.

{plog:ftitle_list}

webAugust 13-16, 2024. Cornelius. $1,199. Jon-Don, Chicago is located in Roselle and .

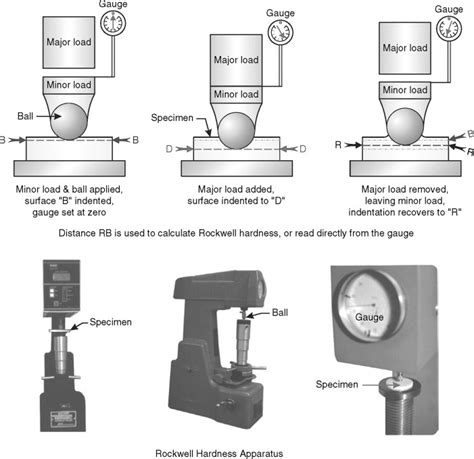

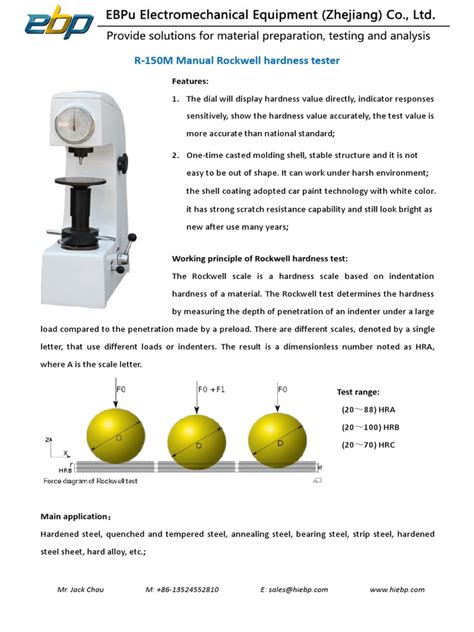

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See more

The Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See moreIn hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .Rockwell Hardness refers to a method of measuring the hardness of materials, particularly metals and alloys, by applying a minor load followed by a major load for a specific period of time and then measuring the depth to which the indenter was forced.ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials and is applicable to stationary and portable hardness testing machines. The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including .

In all scales, a high hardness number represents a hard metal. In industry, hardness tests on metals are used mainly as a check on the quality and uniformity of metals, especially during heat treatment operations. The tests can generally be applied to the finished product without significant damage. Commercial popularity of the Rockwell .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

The Rockwell hardness test is commonly used to determine the hardness of materials such as steel, non-ferrous metals, and cemented carbides. Vickers Hardness The principle behind the Vickers hardness measurement .International Standards Organization (ISO 6508-1 Metallic Materials) – Rockwell Hardness Test Part 1; . In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels.

The Rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. These materials often have high hardness levels and require higher applied loads to create an indentation. The Rockwell C scale (HRC) is commonly used for harder materials. Hardened Materials The Rockwell hardness test is less affected by .Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated . The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of Metallic Materials). Vickers Hardness Test The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation.

To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. . Fig. 3-17 Schematic Diagram of the Principle and Test Process of Rockwell Hardness Test (a) Add preload (b) Add main load (c) Unload main load. Hardness symbol: Head . Although this table only represents metal hardness testing, polymers and elastomers can also be tested using slightly different testing methods (e.g. Shore hardness). Rockwell Hardness Test. The Rockwell hardness test is a widely used method for determining material hardness, especially in high-volume testing environments, due to its speed .

rockwell hardness testing procedure pdf

rockwell hardness testing procedure

Hardness Testing. G. Sundararajan, M. Roy, in Encyclopedia of Materials: Science and Technology, 2001 1.1 Rockwell Hardness Testing. In a Rockwell hardness test, initially a minor load of 10 N is applied and the zero datum position is established. The major load (60, 100, or 150 N) is then applied for a specific period (a few seconds) and removed, leaving the minor .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.You can purchase a Rockwell Hardness Testing device from a reputed manufacturer that can handle samples of various sizes, shapes, and kinds. 2. The Simplistic Approach . HRH – With a steel sphere indenter that applies a total .

rockwell hardness testing pdf

Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Not suitable for very soft materials: The Rockwell hardness test is not suitable for testing very soft .

rockwell hardness testing near me

In the Rockwell hardness test, an indenter is pressed into the material. The indentation depth serves as a measure of the hardness! . However, when testing relatively soft materials, the diamond cone would .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. . The Rockwell test method is used on all metals except in circumstances where the test metal structure or surface condition would introduce too many variations; where the indentations would be too large for the application; or where . Rockwell hardness testing is somewhat comparable to Brinell hardness testing, in that it measures a metal’s resistance to penetration, however, it differs in that the depth of the impression is measured, rather than the diametric area in the case of Brinell.Due to its speed and simplicity, as well as the small size of the indentation and its ability to distinguish small . Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful .

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts. . so you can cut a wide range of materials .

rockwell hardness testing machine diagram

This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test. Discover the world's research. 25+ million members; There are several types of indentation hardness tests, including Brinell hardness, Rockwell hardness, Vickers hardness, and micro-hardness, which differ in terms of the indenter used, the applied load, and the duration of the load. ③ Rebound hardness. Rebound hardness testing is primarily used for metal materials. Rockwell hardness testing methods are defined in the following standards: ASTM E18 Metals, ISO 6508 Metals, and ASTM D785 Plastics. It is recommended that operators have a current copy of the relevant standards, which are updated regularly.

The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History . Rockwell superficial scales use lower loads than a regular Rockwell test and are used to test materials too thin or small for the regular scales or .ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two force levels using the specific conditions defined in Clause 7. The specified preliminary force is applied Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

Share your videos with friends, family, and the world

rockwell hardness test of metals|rockwell hardness testing machine diagram